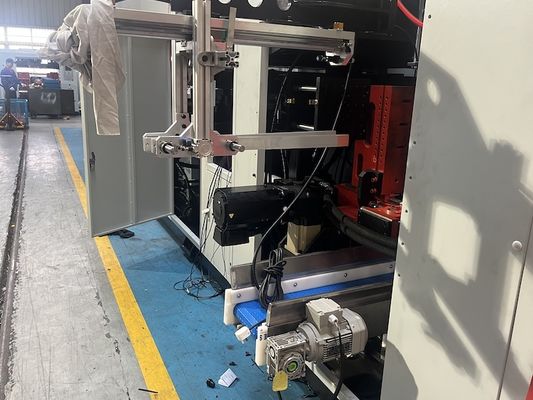

HDPE LDPE PP MP75FD Mesin cetak otomatis

Deskripsi Produk

Mesin Blow Molding Otomatis adalah peralatan industri yang dirancang untuk memproduksi benda plastik berongga, memainkan peran penting dalam pembuatan botol, wadah, toples, dan tangki.Proses ini melibatkan pemanasan bahan plastik sampai lentur, lalu menggunakan udara terkompresi untuk memperluasnya ke bentuk cetakan, memastikan produk akhir yang konsisten dan tepat.Otomatisasi meningkatkan efisiensi produksi dan mempertahankan standar kualitas tinggi dalam pembuatan barang plastik berongga.

Fitur Utama

Operasi sepenuhnya otomatis:Mengurangi biaya tenaga kerja dengan proses loading preform otomatis, pemanasan, meniup, dan ejeksi botol.

Kapasitas Produksi Tinggi:Pilihan multi-kavitas (2-12+ kavitas) menghasilkan 1.000-20.000 botol/jam untuk produksi skala menengah hingga besar.

Kualitas yang konsisten:Kontrol yang tepat terhadap suhu pemanasan, rasio peregangan, dan tekanan meniup memastikan ketebalan dinding yang seragam dan kejelasan yang tinggi.

Efisiensi Energi:Sistem pemanasan inframerah dan komponen servo-driven mengurangi konsumsi daya dengan teknologi pemanasan zona.

Bentuk serbaguna:Sistem pergantian cetakan cepat mendukung berbagai jenis botol (minuman, minyak, kosmetik, farmasi).

Pengguna-FriendlyAntarmuka layar sentuh PLC dengan diagnosis kesalahan dan alarm otomatis untuk pengoperasian dan pemeliharaan yang mudah.

Aplikasi yang luas:Menghasilkan botol PET, HDPE, dan PP untuk berbagai industri termasuk minuman, bahan kimia, dan farmasi.

Operasi 24/7:Dirancang untuk produksi terus menerus, mengintegrasikan dengan mulus dengan mengisi, label, dan garis kemasan.

Spesifikasi Teknis

| Parameter |

MP75FD φ80 |

| Bahan |

PE PP |

| Kapasitas maksimum kontainer (L) |

0.1 |

| Jumlah Die (Set) |

4 |

| Dimensi mesin (L × W × H) (M) |

3.6 x 2,2 x 2.36 |

| Total Berat (Ton) |

5.5 |

| Kekuatan penjepit (KN) |

120 |

| Stroke pembukaan pelat (mm) |

180-480 |

| Kekuatan toggle stroke (mm) |

300 |

| Ukuran cetakan maksimum (W × H) (mm) |

460×450 |

| Diameter sekrup (mm) |

80 |

| Rasio L/D sekrup (L/D) |

24 |

| (HDPE) Kapasitas Plastisasi (kg/jam) |

100 |

| Zona Pemanasan Sekrup (zona) |

4 |

| Kekuatan pemanasan sekrup (kw) |

15.85 |

| Kekuatan kipas (kw) |

0.28 |

| Kekuatan Penggerak Extruder (kw) |

30 |

| Zona pemanasan kepala mati (zona) |

3 |

| Kekuatan pemanasan mati (kw) |

8 |

| Kekuatan Motor Listrik (kw) |

11 |

| Tekanan udara (Mpa) |

0.6-0.8 |

| Kekuatan total mesin (kw) |

65.13 |

| Konsumsi Energi Rata-rata (kw) |

31 |

| Konsumsi Udara Kompresi (m3/menit) |

1.2 |

| Konsumsi air pendingin (L/menit) |

40 |

Aplikasi

Kemasan minuman:Air mineral, jus, minuman berkarbonasi, dan botol teh.

Kemasan makanan:Minyak makan, produk susu, dan wadah bumbu.

Perawatan Rumah Tangga dan Pribadi:Deterjen, sampo, gel mandi, dan produk kosmetik.

Farmasi:Botol obat dan wadah suplemen gizi.

Kimia & Industri:Minyak pelumas, pestisida, dan drum plastik besar.

Rumah & Penggunaan harian:Mainan plastik, toples, dan wadah penyimpanan.

Medis & Kesehatan:Botol disinfektan dan semprotan medis.

Kemasan khusus:Desain prototipe dan botol kosmetik premium.

Opsi kustomisasi

MEPER menawarkan mesin cetak otomatis MP75FD yang disesuaikan dengan sertifikasi CE dan ISO9001: 2008. Fiturnya termasuk diameter sekrup 80mm, kapasitas pemanas sekrup 6kw,dan teknologi In Mold Labeling (IML)Kemasan ekspor standar memastikan pengiriman aman dalam waktu 25-35 hari kerja, dengan syarat pembayaran yang fleksibel (L/C, T/T) dan kapasitas pasokan 100 set/bulan.

Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!  Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!